How to Measure Casters

You can use casters for several applications in many industries like foodservice, medical, and manufacturing. Choosing the right size is as important as picking the right type in maximizing your workplace efficiency.

You need to take five measurements to make sure you’re getting the best casters for your needs:

- Top plate

- Bolt hole spacing

- Wheel size

- Swivel radius

- Overall height

Read on to learn how to take each of these caster measurements.

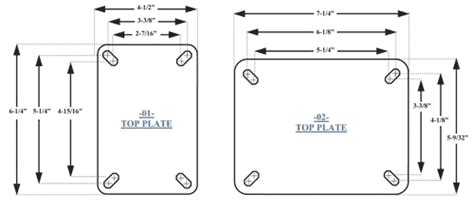

Measure the Top Plate of the Caster

The top plate of a caster fastens it to the desired object. To get the size of the top plate, measure its overall length and width. Top plates are typically 2-⅜” x 3-⅝”, but they come in many sizes. Before getting a caster, measure the area where you will use it.

If you are replacing a caster, measure the existing caster’s top plate to ensure that the replacement will be the same size.

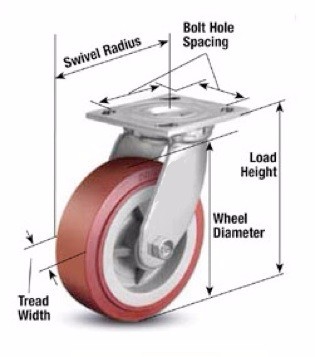

Measure the Bolt Hole Spacing

To get the bolt hole spacing, measure the distance of a bolt hole to the next, starting from the center of the hole. The bolt hole spacing is usually 1-¾” x 2-⅞”.

In most cases, you can’t change the bolt hole spacing of the object you’re buying casters for or of the caster itself. For this reason, you should measure it before purchasing a caster.

Measure the Wheel Size of the Caster

Getting the wheel size of a caster involves two measurements: the width and the diameter.

To get the width, hold the wheel upright and measure one side of the wheel to the other, including the top plate.

To get the diameter, lay the wheel flat on its side and measure it from one side of the other, without the metal attachments.

Wheel size is one of the most crucial factors buyers overlook. If you use the wrong wheel size on any application, you will either have difficulty rolling a caster or find yourself with one that will not stop moving.

Measure the Swivel Radius of the Caster

To get the swivel radius, put the caster down on its side and measure from the middle of the kingpin to the back edge of the wheel. Doing so will get you the swivel radius measurement. It is the point where the tape measure meets the straight edge.

It is crucial to measure the swivel radius if you are using your caster to carry heavy loads. Using the right swivel radius improves the ergonomics and safety of a caster by reducing the required force to move and turn your equipment. The right swivel radius can drastically decrease maintenance, downtime, and workforce accidents.

Measure the Overall Height of the Caster

You can determine a caster’s overall height by measuring the distance between the top plate and the bottom of the wheel.

It is critical to measure a caster’s overall height if you have limited storage or are replacing a caster in a set.

Get in Touch With Caster Experts

So, how are casters measured? You measure the following: the top plate, bolt hole spacing, wheel size, swivel radius, and overall height. Doing so guarantees that your caster will serve your company well for a long time. If you have any questions on how to measure casters, you can call Linco’s caster experts at 866-306-9566 or contact us.